Exploring the Circular Economy Approach in Farm Equipment Manufacturing: 11xplay pro, Diamondexch9, Sky exchange bet

11xplay pro, diamondexch9, sky exchange bet: Exploring the Circular Economy Approach in Farm Equipment Manufacturing

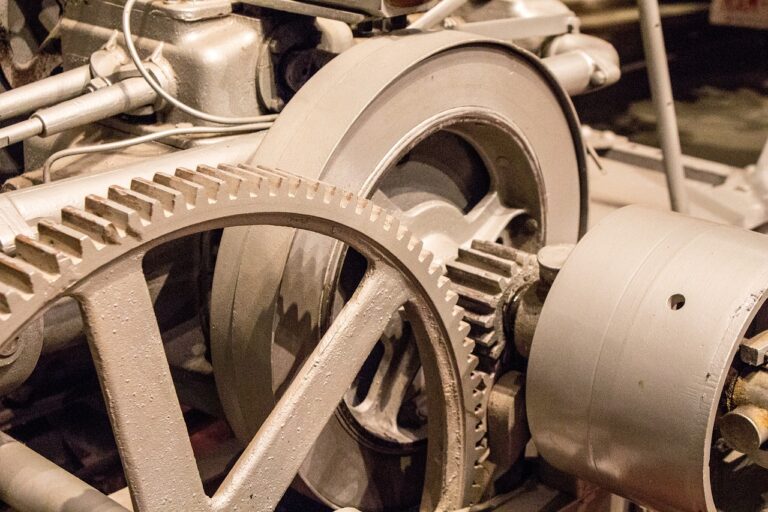

Have you ever stopped to think about the impact that farm equipment manufacturing has on the environment? The production of tractors, harvesters, and other agricultural machinery involves the use of significant amounts of resources and energy, resulting in high levels of waste and pollution. However, a new approach known as the circular economy is changing the way farm equipment is manufactured and used, with a focus on sustainability and resource efficiency.

What is the circular economy approach?

The circular economy is a concept that aims to eliminate waste and create a closed-loop system where products and materials are reused, recycled, or remanufactured. In the context of farm equipment manufacturing, this means designing and producing machinery in a way that minimizes environmental impact and maximizes resource efficiency. This includes using recycled materials, extending the lifespan of equipment through maintenance and repair, and ensuring that products are easily disassembled and recycled at the end of their life.

How does the circular economy benefit farm equipment manufacturers?

Adopting a circular economy approach can bring many benefits to farm equipment manufacturers. By using recycled materials and reducing waste, manufacturers can lower production costs and create new revenue streams through the sale of refurbished or remanufactured equipment. In addition, implementing sustainable practices can improve brand reputation and attract environmentally-conscious customers who are willing to pay a premium for eco-friendly products.

What are some examples of circular economy practices in farm equipment manufacturing?

There are several ways that farm equipment manufacturers can incorporate circular economy principles into their operations. For example, John Deere has implemented a take-back program where customers can return old equipment for refurbishment or recycling. Case IH has introduced modular design concepts that make it easier to repair and upgrade machinery, extending its lifespan and reducing the need for new production.

How can farmers contribute to the circular economy?

Farmers can also play a role in promoting the circular economy by choosing equipment that is durable, energy-efficient, and easy to maintain. Regular maintenance and proper storage can help extend the lifespan of machinery, reducing the need for frequent replacements. Farmers can also explore options for buying used or refurbished equipment, further reducing demand for new production.

In conclusion, the circular economy approach is revolutionizing the way farm equipment is manufactured and used, with a focus on sustainability and resource efficiency. By adopting circular economy practices, farm equipment manufacturers can reduce waste, lower costs, and attract environmentally-conscious customers. Farmers can also contribute to the circular economy by choosing durable equipment and practicing proper maintenance. Together, we can create a more sustainable future for agriculture.

FAQs

1. What is the circular economy approach in farm equipment manufacturing?

The circular economy approach in farm equipment manufacturing focuses on eliminating waste and creating a closed-loop system where products and materials are reused, recycled, or remanufactured.

2. How can farmers contribute to the circular economy?

Farmers can contribute to the circular economy by choosing durable, energy-efficient equipment, practicing regular maintenance, and exploring options for buying used or refurbished machinery.

3. What are some examples of circular economy practices in farm equipment manufacturing?

Examples of circular economy practices in farm equipment manufacturing include take-back programs for old equipment, modular design concepts for easier repair and upgrading, and using recycled materials in production.